Asset Integrity Monitoring (AIM)

PARTIAL DISCHARGE (PD), ROTOR FLUX, ENDWINDING

VIBRATION (EWV) AND SHAFT VOLTAGE AND CURRENT

Asset Integrity Monitoring - Our solution for accurate and actionable results

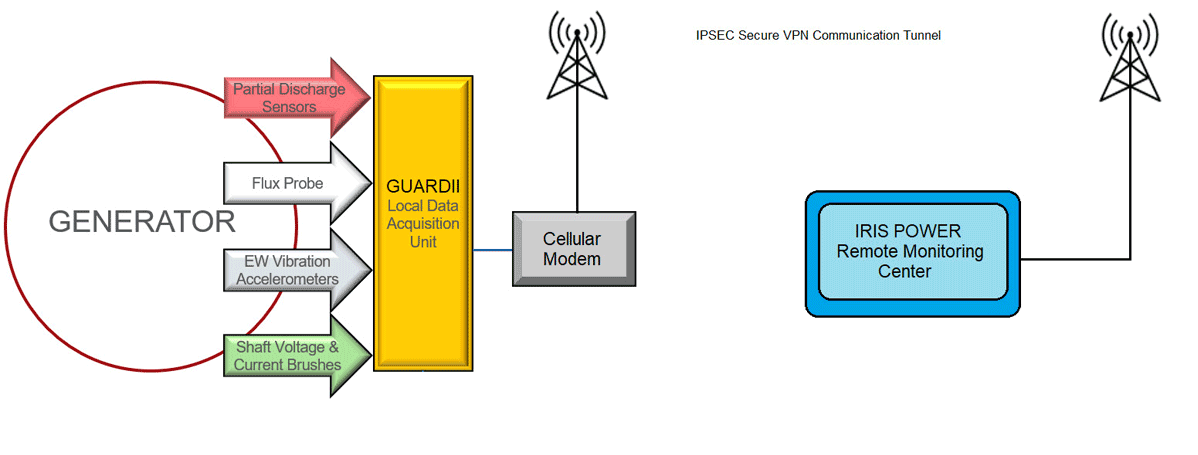

The Asset Integrity Monitoring (AIM) program is our solution to delivering, machine expert interpreted results and recommendations. Along with providing continuous on-line remote monitoring for partial discharge (PD), rotor flux, endwinding vibration (EWV) and shaft voltage and current (SM); we introduce the AIM solution to take you the next step in monitoring your valuable assets.

Why AIM?

- Identification and timely recommendations of symptoms of impending failures

- Significantly reduced man hours for PD/Flux/EWV/Shaft data collection and analysis, equipment maintenance, etc.

- No customer input required, completely hands-off solution

- Asset watch with email alerts (electronic delivery)

- Comprehensive reports – twice yearly

- Uses a cellular network that is completely independent of plant infrastructure

- IPSEC secured encrypted VPN data transmission

- Access to the latest monitoring technologies

- Enhanced workflow and resources planning

- Fixed prices for the duration of the contract

- Administrative efficiency (reduced PO, invoicing, auto-scheduling)

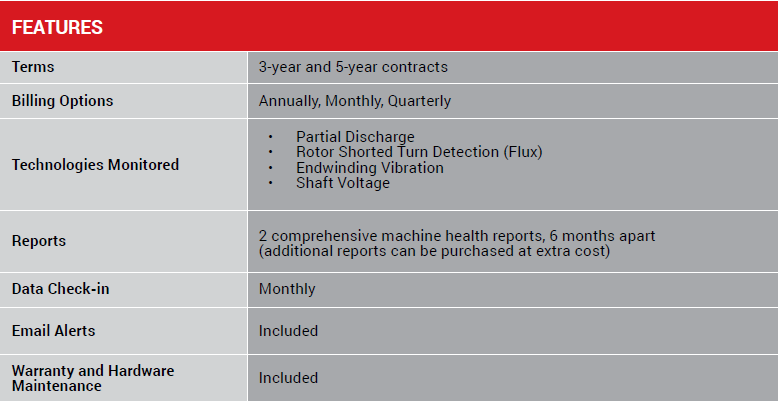

- Flexible payment terms and contract durations (3- or 5-year term available)

BENEFITS OF CONDITION BASEDMAINTENANCE ON GENERATORS

- The time between generator shutdowns can be extended if monitoring reveals that the rotor and stator are in good condition. This increases availability and helps to avoid failures caused inadvertently during the shut-down inspections (such as leaving a tool in the machine).

- Problems can be found at very early stages, allowing for a maintenance shutdown to be planned at a convenient time. Experience also shows that if most problems are detected at an early stage, repair costs are often less than 1% of the rewind cost that would be incurred if the failure were permitted to occur in-service.

- Rewinds and other major repairs are based on need rather than the calendar or operating hours – or the desire of machine manufacturers and service organizations to generate after-market revenue.

Ready to Learn More?

THESE MONITORING TECHNOLOGIES INCLUDE:

- Reliable measurement of stator winding partial discharges (PD) using on-line methods.

- Detection of shorted turns in generator rotor windings using magnetic flux monitoring.

- Detection of stator endwinding vibration.

- Rotor shaft ground brush current and voltage monitoring.

The Iris Power GuardII+ monitor has been designed to be a continuous monitoring platform to incorporate one or more of the above technologies into a single, flexible format with a common hardware platform, database and interface. With all these on-line monitoring technologies, as well as temperature monitoring, the majority of generator aging problems can be detected and addressed well before in-service failures occur. Qualitrol-Iris Power and its staff have been at the forefront in bringing these new monitoring technologies to utilities.

MANAGE YOUR RISK

Qualitrol-Iris Power is the

world’s largest provider

of asset monitoring and

diagnostics solutions for

high voltage motor and

generator windings.

IRIS POWER | GUARDII+

>80k

Global sensor installs on rotating machines

#1

Online monitoring provider for motor and generator windings

>700k

Test results in Iris Power’s on-line Partial Discharge database